Science cluster

Summary

Metal additive manufacturing (MAM), central to Industry 4.0, has drawn significant interest in sectors such as medical, aerospace, energy, and automotive. However, widespread adoption remains limited due to concerns over inconsistent material properties and a lack of full understanding of how novel microstructures impact performance. To address these challenges, the OpenCorrAM project will investigate the corrosion behaviour of additively manufactured materials, such as austenitic stainless steels, nickel-based superalloys, and titanium alloys. Using high-resolution microscopy, microcapillary electrochemical techniques, and surface analysis, the project will study passive layer formation and breakdown. By comparing AM materials with conventionally manufactured ones, it will provide new insights into corrosion science. Project findings will benefit industry, research, and policymakers by improving material performance, sustainability, and safety.

The project team will develop a comprehensive, open-access database that interrelates processing, (micro)structure, and performance of AM alloys, with focus on corrosion aspects. This database will advance the state of knowledge, foster innovation in materials science and engineering, and help overcome barriers to the broader implementation of MAM technologies.

Challenge

Open Science project, Industry cooperation, Main RI concerned, Cross-domain/Cross-RI

The growing adoption of MAM faces significant hurdles, particularly the high variability in material properties and the unclear connections between novel microstructures and their performance. This inconsistency limits the full-scale implementation of MAM across industries requiring reliable corrosion resistance, such as aerospace and energy. The need for a systematic approach to understanding the corrosion behaviour of additively manufactured materials is crucial for fostering confidence in their use.

Solution

Employing advanced high-resolution and microcapillary electrochemical techniques, OpenCorrAM strives to create an open and comprehensive database of intercorrelated results in the different fields of MAM performance analysis, that catalogues the corrosion characteristics of various additively manufactured materials. These investigations serve to provide exceptional insights into micro and submicron structural details, as well as the electrochemical and corrosion properties. Machine learning techniques will analyse the data, establishing relationships between microstructural features and corrosion behaviours, thereby enhancing predictive capabilities in materials performance.

Scientific Impact

OpenCorrAM not only enhances the scientific understanding of corrosion in additively manufactured materials but also revolutionises the field through the establishment of an open-access knowledge base.

By enabling access to a broad collection of data and findings, and by integrating machine learning techniques to analyse data and identify relationships between microstructural features and corrosion properties, OpenCorrAM helps standardise methods and approaches in corrosion studies related to AM materials, responding to the widely recognised strong need to open corrosion data to develop and feed predictive models in corrosion science. The project thus fosters collaboration and innovation, driving advancements in corrosion studies and supporting the MAM industry’s growth.

Results

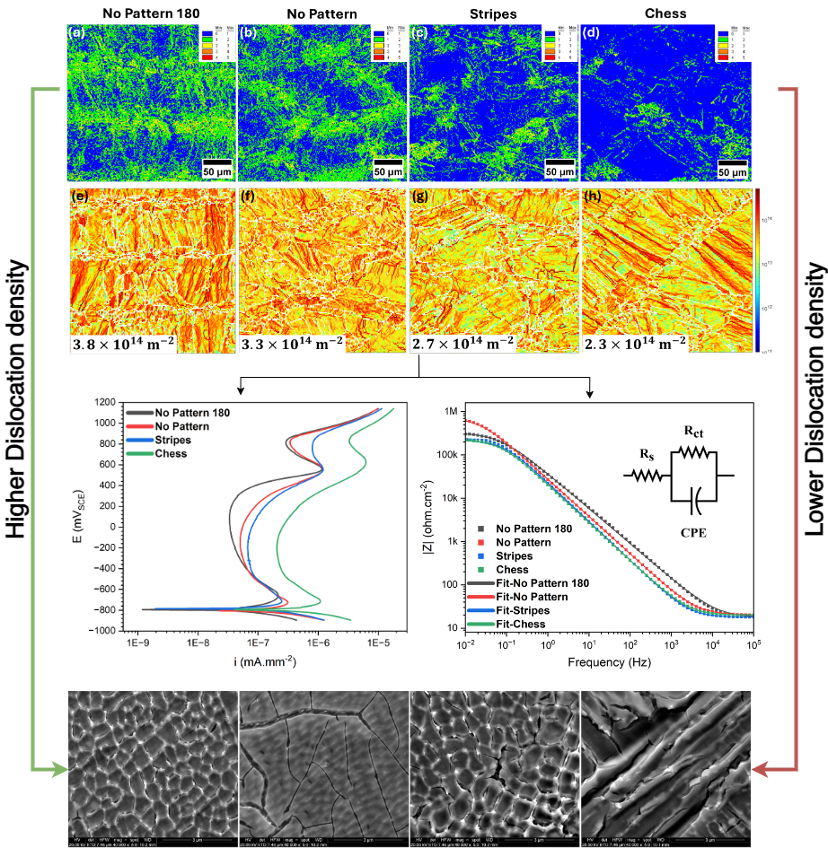

- Building the Foundation: Corrosion Data Collection of AM Alloys Underway: The OpenCorrAM project has successfully launched a structured and continuous corrosion data collection effort focused on additively manufactured (AM) nickel-based alloys, austenitic stainless steels, and titanium alloys. This marks a critical milestone toward the creation of a comprehensive open-access database linking corrosion behaviour, microstructure, and processing routes of AM metals. Using a combination of electrochemical polarization testing, high-resolution microscopy, and surface characterization techniques, the project team has begun compiling extensive datasets. These include passive film stability, pitting behaviour, and localized corrosion responses, all correlated with microstructural features such as grain and dislocation structure, defect distribution, and surface chemistry. To ensure robust comparisons and meaningful insights, data from AM materials are also being benchmarked against conventionally manufactured counterparts. This approach will help identify the main AM microstructural features and isolate the effects of additive-induced microstructural heterogeneity on corrosion performance.

Publications

- Passivity and breakdown mechanisms in laser powder bed fusion processed Ni-based Alloy 625: Influence of scan strategy | DOI

Events

- 9-13 June, 2025 | Western University, London, Canada, and online - Corrosion Science Institute Summer School (CSI-2025)

- 11 September, 2025 | Stavanger, Norway - EUROCORR 2025 - Promotion of Open Science data for OpenCorrAM

- 14-18 September, 2025 | Granada, Spain - EUROMAT 2025 - Promotion of Open Science data for OpenCorrAM

Promotional material

- Video recordings of the talk on the fundamental concepts of FAIR and Open Science given by OSCARS contributor, Paul Millar, at the Corrosion Science Institute Summer School (CSI-2025)

Principal investigator

Reynier I. Revilla earned his PhD in Physical Chemistry in 2014 from the National Center for Nanoscience and Technology, Beijing. Since 2016, he has been a postdoctoral researcher at VUB, focusing on multiscale analysis and surface engineering of additively manufactured metals. His work includes surface treatments, corrosion protection, and development of nanoscale metrology concepts. He has 52 peer-reviewed articles, 65+ conference contributions, and has supervised 6 PhD and 15 Master students. He is currently a Young EFC board member and co-chair of the EFC Additive Manufacturing Task Force.